Who we are

Since our inception in the 1988, we have been a prominent manufacturer in the sealing & packaging machine space in India, catering to diverse sectors of the industry.

Our specialisation lies in designing and manufacturing the machines as per customised specifications of our client. Our exclusive sealing system locks and seals individual packages by providing a long consecutive seal in both types – horizontal and vertical.

Our manufacturing infrastructure supports the production of automatic, semi-automatic as well as manual sealing machines. The SealOpack brand owes its recognition and image to the superior machine quality and durability coupled with its after-sales service. It is through constant optimisation of our processes applying the Kaizen principles that has ensured the production of world-class regulation machinery at the most reasonable prices. Band Sealers, Pneumatic Sealers, Carton Taping Machines, and other instruments form part of the SealOpack machinery line. Illustratively, our satisfied clientele belong from the following sectors:

A Dedicated and Accomplished Workforce.

Our facility is staffed by a team of highly creative and certified professionals whose collective energy is dedicated to successfully executing every assigned responsibility with distinction and meticulous attention to detail.

Guaranteed Product Integrity

Through our defined Quality Assurance Plan (QAP), we guarantee maximum product integrity. This is achieved by subjecting both our final machinery and all third-party components to meticulous, high-level testing and quality checks.

Deep-Rooted, Scalable Knowledge

We hold in high regard the technical acumen developed over our 20-year history. This experience is uniquely underpinned by the massive scale of our achievements: the successful installation of more than 500 pharma facilities worldwide.

Bespoke Solutions for Total Fulfillment.

We are deeply committed to providing utmost client satisfaction. This commitment is realized through the provision of customized solutions that offer unique value and high differentiation compared to standard offerings.

Why us

Blister & strip-packing machines – For tablets/capsules in unit-dose packs. They form cavities (or strips), fill the product and seal foils.

Filling & capping machines – For liquids, syrups, suspensions or solids in bottles/vials. They ensure accurate fill and secure closure.

Cartoning, bundling & case-packing machines – For secondary/tertiary packaging: placing primary units into cartons, wrapping/shrink-bundling, and case-packing for transport.

Labeling and coding/inspection machines – Essential for applying labels, printing batch/expiry codes, and verifying integrity/traces.

Special aseptic/sterile packaging equipment – For injectable/sterile forms, such as blow-fill-seal (BFS) machines.

Pouch / sachet machines – For powders, granules, liquids, small-pack formats common in FMCG (e.g., single-serve detergents, sauces, snacks).

Form-Fill-Seal (FFS) machines / Bagging machines – Machines that form packaging (from roll film), fill with product (solid, liquid, granule) and seal, ideal for high-speed FMCG operations.

Filling & capping machines – For bottles, jars, containers used in beverages, personal care, edible oils, sauces.

Cartoning, bundling & case-packing machines – For secondary and tertiary packing of FMCG products: inserting into cartons, wrapping multipacks, prepping for shipping.

Labeling & coding machines – For applying labels, printing batch/expiry, barcodes, etc.; necessary for branding and traceability.

Film‐blowing / extrusion machines: Produce plastic films (PE, PP, etc) used for bags, wraps, liners.

Thermoforming / tray forming machines: Heat plastic sheets, form them into trays, cups, containers.

Bagging/Granule packaging machines: For packaging plastic granules/resins into bags (10–50 kg or bulk).

Sealing / Wrapping / Case‐pack machines: Seal pouches/bags, wrap multiple items, palletise for transport.

Injection/Blow moulding machines: For producing plastic bottles, containers and then packaging them.

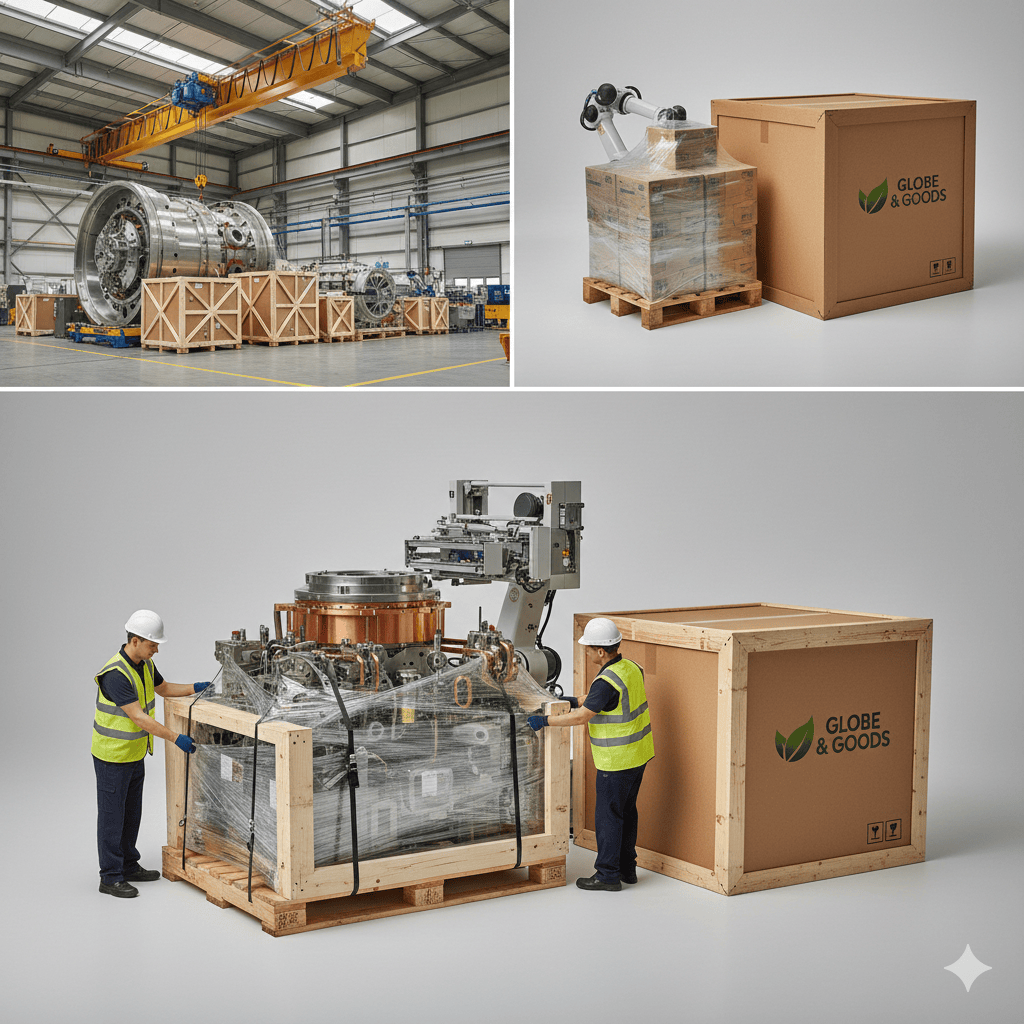

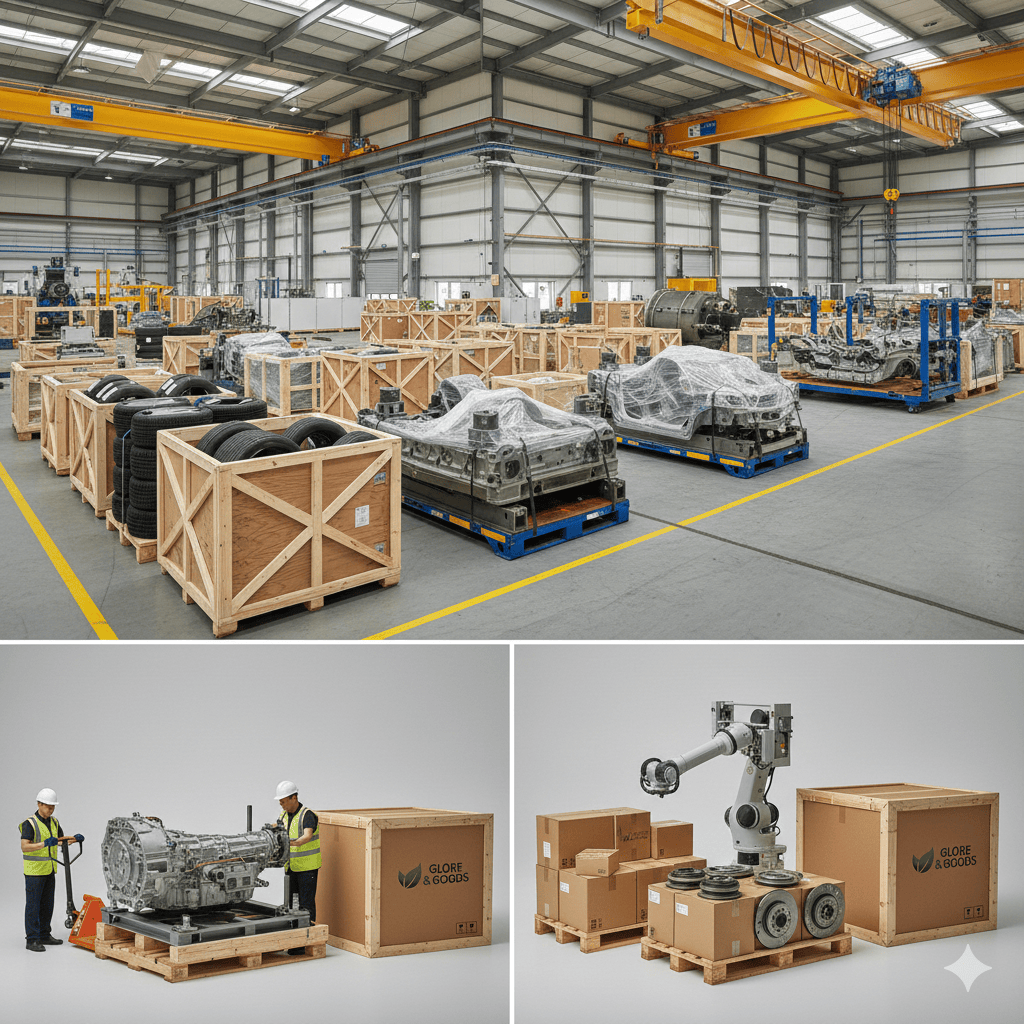

Strapping & banding machines – Used to secure heavy or oversized bundles (e.g., metal parts, tubes, engineered components) with plastic/PET bands or steel straps. Ensures stability & safety in transit.

Case erectors / case packers / box forming machines – Build/erect rigid boxes or crates for engineered goods, then pack components into those boxes, seal them for shipment.

Palletisers / robotic palletising systems – For large engineering goods, packed cases or heavy items need to be stacked and secured on pallets; automation aids throughput and safety. Packaging Labelling

Wrapping / shrink‐wrapping machines – Wrap large units, assemblies or skewed sized items in stretch wrap or shrink film to protect against dust, moisture and transit damage.

Bagging / bulk-packing machines – For engineered components like fasteners, small parts, granules, or resin etc., machines that fill bags/sacks, weigh and seal.

Bagging / pouch-packing machines – For smaller components like bolts, clips, seals, filters etc. These machines count/fill the parts and seal them into bags or pouches for shipping or storage.

Case erectors, case packers & sealers – For medium to larger components or kits (e.g., engine parts, sub-assemblies). These machines erect boxes, fill them with products, and seal/close them.

Palletizing & stretch-wrapping machines – For heavy/larger items or bulk shipments in pallets. The parts are packed into cases, stacked on pallets, then wrapped/secured for transport to protect from damage, shifting, dust.

Flexible format machines for odd shapes & kits – Many automotive parts are irregular in shape or combine several smaller parts into a kit. Machines exist that handle these special cases (counting modules, custom feeding, bespoke packaging).

Filling & capping machines – For liquids, creams, gels, serums packed into bottles, jars, tubes. These machines must handle varying viscosities and container types.

Tube-filling/sealing and jar/pot packaging machines – For products like tubes of creams or jars of balm.

Cartoning / Over-wrapping / Secondary packaging machines – To pack the primary container into a box or wrap it for retail presentation.

Labeling/decoration & special finishing machines – Cosmetics rely heavily on strong visual appeal, so machines for decorative printing, hot stamping, and precise labeling are important.

Form‐Fill‐Seal (FFS) / Vertical Form Fill Seal (VFFS) – Machines that take a roll of film, form a pouch/bag, fill the product and seal in one step. Ideal for snacks, powders, granules.

Horizontal Flow Wrapping / HFFS – Wrapping solid items (like bakery goods, candies, bars) in continuous film horizontally.

Vacuum Packaging / Modified Atmosphere Packaging (MAP) – Removing air or replacing with inert gas to extend shelf life of perishables (meats, cheeses, ready meals).

Bagging / Open‐Mouth Bag Fillers – For bulk dry foods: rice, sugar, cereals, powders in bags or sacks.

Filling, Capping & Tray Sealing Machines – For liquids (beverages, sauces), ready meals (tray sealed), or jars/bottles.

Our Esteemed Clients